3D printing is getting more affordable with the advancement of technology. The potential is limitless; you can easily build prototype, moulds or literally anything you can think of. You will be mesmerized by the quality of the 3D printer.

Our picks vary in functionality, price, type, and size so that you can select what suits you. These printers are for both the noobs and the experts out there. So, let’s dive in.

Contents

What is 3D Printing

3D printing or additive manufacturing is a process of making three dimensional solid objects through a layering method. It uses a combination of computer-aided design (CAD) and power like materials to create a precise 3D object from scratch.

The printing is done by laying down successive layers of plastic, metal or composite materials. This process is more efficient and uses fewer materials than the traditional manufacturing method.

Types of 3D Printers

FDM and SLA Printers are the most popular 3D printers on the market. We will be sharing if you which option is better for you based on your printing needs.

Fused Deposition Modeling (FDM)

In an FDM printer, the thermoplastic filament is heated and pushed into the extruder. The filament is melted and deposited through the nozzle onto a printing platform in a layering process to create the object.

FDM printers are affordable; they have a wide range of printing materials to choose from and produce a prototype fast. However, FDM tend to have lower dimensional accuracy and resolution and requires post-processing for a smoother finish. It is commonly used for prototyping and non-commercial use.

Stereolithography Apparatus (SLA)

SLA is synonymous with resin 3D printing. SLA uses a liquid resin material to print objects through a vat photopolymerization process. It selectively hardens the liquid polymer by shining UV light through the vat’s see-through bottom. The build plate is then moved to the next layer and exposed to the UV light again. This process is repeated till the 3D object is created.

Compared to FDM, SLA can create a smoother surface and with more detailed 3D objects. It is also faster and can produce stronger objects because of the better layer to layer adhesion.

SLA uses photosensitive thermosetting plastics in a liquid resin form. These materials are more costly and have limited colour selections. It is ideal for commercial applications like dental crowns, which require high strength and precision.

What To Look For In A 3D Printer

It all depends upon the following factors:

What you want to print:

Figuring out what you want to print and what kind of print you want is better before moving further.

For printing larger object, or objects that do not need micrometre scale layers which results in a smoother surface. Then FDM is probably better suited to you. These printers can print areas measuring 220mm X 220mm X 200+mm (X/Y/Z).

Suppose you intend on creating intricate or smaller objects like jewellery or dental crowns. Then it would be best if you went for SLA or resin-based printer.

Ease of use:

The ease of usage of a product is the most important thing. If we cannot use the 3D printer easily and not get hold of it, then it is of not much use. One cannot get the most out of that particular printer.

A good 3D printer will have the following qualities:

- Advanced software that is easy to understand and makes the printing process quicker and simple

- A good UI design and screen to guide you through steps such as adjusting the extruder and changing filaments

Hot End

The hot end of the 3D printer is the most important part of it. This is the part where the plastic along is melted, and layers are created. Many different types of hot ends are available in the market.

The important components of a hot end are:

- Active cooling

- Maximum temperature of the printing

- Size of the Nozzle and options to change it

Two types of Hot ends are used commonly which are

- Peek-based Hot ends require more maintenance and cleaning, it can get jammed easily. The maximum temperature limit for them is 230°C.

- All-Metal Hot End works with all kinds of materials, are jam-free, and give out cleaner prints. It has a max temperature limit of 320°C

Nozzle Size:

The nozzle is the tip of the hot end through which the material like plastics comes out. You need to change it when required. The nozzle size is crucial and varies from 0.25mm to 0.75mm, with 0.5mm being the most commonly used size. The best way is to get the nozzle size according to the design and demand of the print.

A smaller nozzle size creates a smoother finish as it means thinner lines extruder and smaller layer height which gives an overall clean and better finish to the part of the model; Accurate prints; more detailed prints, and more ridge parts because more closer and thin lines are added to each other with the small nozzle.

Larger nozzle size provides faster printing, less support, better reliability, and first-layer adhesion. Thicker strings are produced, which reduces the number of layers.

Extruder:

The extruder is another important part of the 3D printer. It is the part that feeds the filament to the nozzle. There are two main kinds of extruders available in the market.

Direct extruder: It is the extruder in which the filament is fed to the hot end through the motor spindle. This is the mechanism through which the extruder is mounted onto the hot end. It allows more accuracy along with finer control and is easier to work with.

Bowden extruder: The filament is fed to the hot end through a distance, and both the extruder and hot end are not connected. So, the filament has to travel a long distance until it reaches the end of the hot end. It not only reduces the weight but also helps in quicker movements and fewer vibrations.

Best 3D Printers

Our picks vary in functionality, price, type, and size so that you can select what suits you. These printers are for both the noobs and the experts out there. So, let’s dive in. These are some of the best 3D printer’s list we curated for you:

1. Formlabs Form 3 – Best SLA Printer

Why We Love It

Formlabs Form 3 is a printer based on SLA technology.

When the Formlabs Form 3 printer was introduced, its impressive work made the printer accessible and affordable. It was not initially available to everyone. However, when its demand increased due to the accuracy of its 3D prints, its size and price both were made appropriate and reduced.

It was firstly based on the only SLA, but in recent times, the system of this 3D printer is upgraded to the Low Force Stereolithography (LFS), which is much better and quicker. Talking about its build, the 3D printer has a transparent base of the build tank. The lasers, optics, and other machinery are put below this build tank to make everything visible and under supervision.

When the printing process starts in this printer, the build tank moves upward incrementally, and each layer of the model is built in a tank of UV Curable resin. The UV light helps in the curing of layers in place. This helps you in making colourful dental structures and dentures.

The Formlabs Form 3 transforms the way you deal with biocompatible materials. This machine is recommended and is the best for the people who are dealing with the medical profession. They can get 3D prints of the biocompatible and the non-biocompatible structures.

Some important features of this 3D printer are:

- This 3D printer can run24/7 with smart sensors

- Best for remote printing

- Parts can easily be cleaned

- Replaceable parts

- Cartridge system easily allows you to switch between the resins

- High-resolution screen

- 5.5 Inches big screen

Keep In Mind

The issue is that it has a rigid build platform, so when one layer is built to add in other layers, you need to lift the platform a bit for other layers, but this causes suction between the part on the build platform and the window below. This can impact the resin and can impact the resin tank’s integrity.

2. Elegoo Mars 2 – Ideal For Beginner

Elegoo Mars 2 3D printer is the best pick when it comes to affordability and effective work.

Why We Love It

Let’s look at the printer at a glance,

- Method Used: MSLA

- Resolution: XY: 47 Z: 10

- Consumable Tech: 5.5″ 2K LCD (~$30)

- Max Build Volume: 120 x 68 x 155

- Batteries Required: No

The sturdy structure of the all-aluminium fuselage plus acrylic cover, which is elegant and durable. The Elegoo Mars 3D Printer is a basic printer that affordable and packed with features. The low price does not compromise the print quality; it gives effortlessly brilliant prints. The print preparation workflow is easily accessible.

The latest fast slicing CHITUBOX software gives the users an extraordinary experience. And takes up to 1 min to make 30 Mb.stl model files and 10 mins to complete the model.

Its resin saving and better printing qualities help make the resin hollow before slicing the model, which reduces the waste of resin drastically during the photocuring process. Its better printing result is due to the use of 40W UV lights and ELEGOO resin.

Talking about its display, it is equipped with a 3,5 inches touchscreen which makes offline printing easy. You can start the printing process within 5 minutes of its assembly, and this is due to the steel-ball balancing structure within the build platform.

It is high-resolution, and high-precision uses a masking LCD to provide you accurate printing.

Keep In Mind

Though the 3D printer has a low price tag, its accessories and supplies can add to the cost. Another thing that should be in your notice is that the printer gives out a high-pitched beeping noise that cannot be deactivated. It is smaller than the typical build volume.

Get Elegoo Mars 2 Printer From Amazon

3. Creality Ender 3 V2 – Popular FDM Printer

A durable and affordable silent 3D printer.

Why We Love It

This 3D Creality Ender 3 V2 has a self-developed silent motherboard which is one of its best features. The motherboard has strong anti-interference, faster and more stable motion performance. It allows silent printing and low decibel performance, which makes the whole printing process noise-free.

Talking about its power supply which is by MeanWell, giving the bests user experience. It is produced by a UL-certified listed company based on mature technology, meeting all the needs, including fast printing and long-time printing. You can use it day and night for printing out your favourite and most desirable models with the best and accurate details. The company has made the power supply much safer by concealing it within the machine.

It has set a new baseline for budget 3D printing. The Creality 3D printer is much stable, durable, and firm. Isn’t it so desirable of a product? The printer’s platform heats up quickly, which allows the print to adhere properly without warping up. So, you will find ultra-smoothness even on the first layer of the model.

Keep In Mind

There are some downsides of this Ender 3 V2 printer:

- It has only one motor at the Z-axis

- A touchscreen interface is absent in this like other modern printers

- Ringing in beds can be heard as the glass beds are heavier.

Get Creality Ender 3 V2 From Amazon

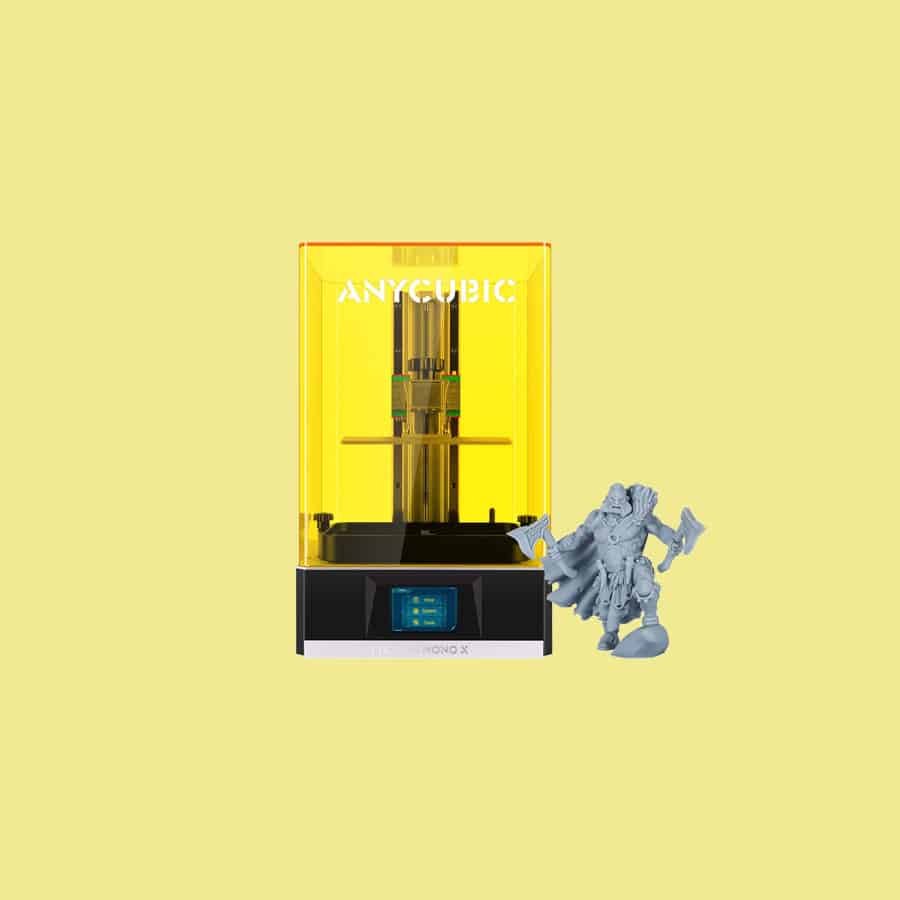

4. Anycubic Photon Mono – Affordable Resin 3D Printer

Why We Love It

Let’s have a look at its features:

- Display: 2.8 inches Touch Screen

- Software: ANYCUBIC Photon workshop / ChituBox

- Connectivity: USB

- Technology: LCD-based SLA

- Printing Speed: MAX 50mm/h

ANYCUBIC printing speed is 2.5X faster than regular 3D printers like the ANYCUBIC Photon 3D printer; rapid prototyping is improved, which has also improved printing efficiency saves time as well.

It exhibits high accuracy and strong stability. The printed screen is equipped with 15 pcs lamp beads that can carry out uniform exposure throughout the screen and improve the quality of models made.

This 3D printer is great for printing out toys, cartoon characters, games, miniatures, and movies, etc. It Z-axis guide rail structure fats stepper motor has better stability. The 3D printer is easy to use and brings out outstanding prints.

Beginners should get their hands on this one as this gives good performance and is also cost-effective.

Keep In Mind

You can have a problem with the touch display screen as it is tiny. People with thick or bigger fingers will find it difficult to operate the printer through the LCD screen. Also, the user interface will take some time to get there.

One more downside with this printer is that you would need to give it more space for getting prints if you insert a USB, and the USB port should be out-front.

Get Anycubic Photon Mono From Amazon

5. Mayku FormBox – Compact 3D Printer

MAYKU FormBox is a printer that makes your ideas look real.

Why We Love It

The FormBox is a concise and compact printer and helps you get prints whether you get print by hand or use a desktop. It fits into your workspace very easily. You can create a factory-finish product without a factory.

To get an industrial-style vacuum forming, you just need to attach a vacuum cleaner with your printer, and there you go! This can be done in your home or your office. Ain’t this so convenient?

The FormBox printer comes with easier and smart settings. It does not make 3D printing a hectic process. Rather it is simple and gives you the exact finish. It picks up the texture and design finer than the grain particles so that you will get all your desired details in your 3Dprinted model.

The integrated ceramic heater with a temperature range of 160c to 340c prepares your plastic for proper forming. The cooling system of the printer is also very efficient.

Keep In Mind

The major downside of it is that It does not have a vacuum of its own. You will need to attach an external vacuum to it, as explained above. Also, it is not as cheap as a DIY printer. So, keep those points in your mind when purchasing the MAYKU FormBox 3D printer.

6. Markforged Metal X – Precise Metal Printing

Why We Love It

The 3D printing technology used in this 3D printer is known as Atomic Diffusion Addicted Manufacturing (ADAM), which involves using metal powders instead of composite materials. This method effectively reduces the risks involved in traditional metal 3D printing.

The best thing about this printer is that it reduces production costs and reducing part weight. Other traditional 3D printers have escape holes for getting rid of the unused powder. However, this is not the case with this one. It burns the unused powder during the sintering process. This reduces the mess and the waste as well.

Out of many advantages of the Markforged Metal X 3D printer, one is that it can create complex geometric off-parts of the model. It helps in the creation of 3D prints affordably than the overburdening the manufacturers increasing the manufacturing costs. The process is quicker, but it is not short. It requires extensive post-processing.

To begin the 3D printing process, it is a good entry point for both the businesses and the manufacturers. They can start making the end-use metal parts of the machines and other products.

Some important features of this 3D Printer are as follows:

- Printing Process: Metal FFF

- Printing media: Bound Powder Filament

- Internal part Geometry: Closed-cell Infiller the solid parts

- Z-layer Resolution: 50 μm – 125 μm (Post-Sinter)

Keep In Mind

This printer cost a whopping $100K; it is mainly targeted towards commercial usage.

Get Markforged Metal X 3D Printer

Wrapping Up

Now that we have reached the end of this article, you would have understood the basics of the 3D printers, the best choices to be made, and why you need them. All these points need to be kept in mind while purchasing a 3D printer for yourself.

They help in bringing you the perfect 3D prints of your models, or whatever useful things you want to get printed with perfect and clean details. We hope all this has helped you make a better choice.